Our revealed circuit board (PCB) meeting substances provide terrific overall performance and excessive productivity. Moreover, the circuit board adhesive facilitate device financial savings and decrease era investment, including for your customers’ backside line. Being capable of in-shape substances for PCB assemblies offers consistency in production procedures and product overall performance.

We provide a vast variety of PCB adhesive merchandise, from a couple of chemistries with a couple of PCB meeting applications, inclusive of urethane, acrylic, epoxy, and silicone chemistries—all of that are utilized in conformal coatings, adhesives (die attach, floor mount, thermal conductivity) and potting/encapsulants.

In addition, tool reliability is an essential degree of product overall performance withinside the electronics enterprise, whether or not the utility is for customer or business meeting applications. H.B. Fuller’s variety of excessive-overall performance underfill and edge bond substances provide dependable structural reinforcement of touchy tool additives in addition to balanced re-workability, relying on unique patron requirements.

Printed Circuit Board Assembly

From conformal circuit board adhesive coatings to floor mount adhesives or from conductive movies to thermal control merchandise, Master Bond is main the manner in digital meeting applications. Our line of epoxies, silicones, polyurethanes, polysulfides, cyanoacrylates, and UV therapies function progressive answers to difficult enterprise requirements.

Benefits of Master Bond Electronic Grade Compounds

Master Bond is actively engaged in growing new merchandise for superior digital systems. Our compounds provide the subsequent advantages:

- Widest variety of formulations

- Consistent reproducible excessive overall performance systems

- Latest era

- Easy utility—easy packaging (inclusive of premixed and frozen syringes)

- Available direct from the manufacturer

- Custom formulations available

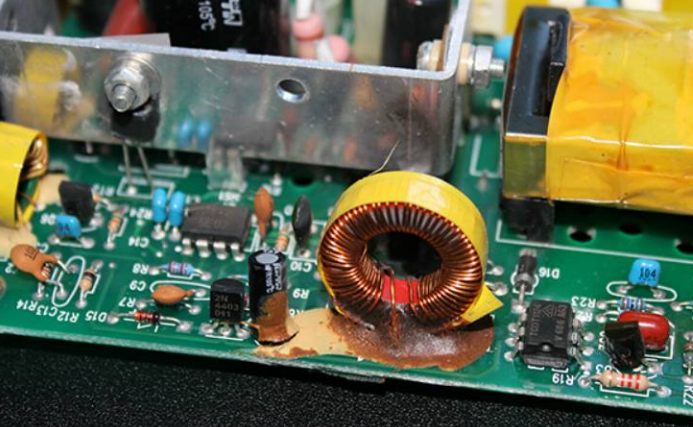

Bonding Small Electronics to Printed Circuit Boards

A patron examined an adhesive bonding utility in-house: specifically, the engineering group bonded a small element to a pitcher substrate to check the adhesive.

The adhesive labored well. However, while the group examined the identical adhesive on a published circuited board (PCB), the board warped after therapy. They were referred to as Apple-Tec for help.

The trouble became two-fold:

1. Because the skinny board wasn’t inflexible enough, it became warping because of the adhesive shrinking at some stage in the therapy process.

2. The adhesive became shrinking due to the fact the therapy temperature became too excessive. The excessive temperature became an additional setting strain on the board.

Bonding additives to PCBs are distinct from metallic-to-metallic bonding (e.g., aluminum to aluminum). Rigid PCBs are crafted from fiberglass, composite epoxy, or different cloth and accordingly reply in another way to warmness than conventional substrates including glass or aluminum.

High temperatures generated with the aid of using additives at the board can motivate harm and malfunctions – that’s why warmness sinks and thermally conductive adhesives are used to direct warmness far from additives.

The circuit board adhesive generated at some stage in soldering also can motivate thermal strain on additives and might result in board failure.

And, because the engineering group learned, severe warmness at some stage in the therapy cycle became first-class for a pitcher substrate, however now no longer have their skinny forums nor the adhesive they had been using.

As a part of our process, Apple-Tec can advise adhesives that therapy at decreased temperatures, accordingly decreasing strain on forums and additives, in addition to strain because of shrinkage.

We also can advise electrically conductive adhesives that may update solder for temperature-touchy additives.

Apple-Tec has a huge type of adhesives with verified skills to bond additives to PCBs and faces up to harsh environments.