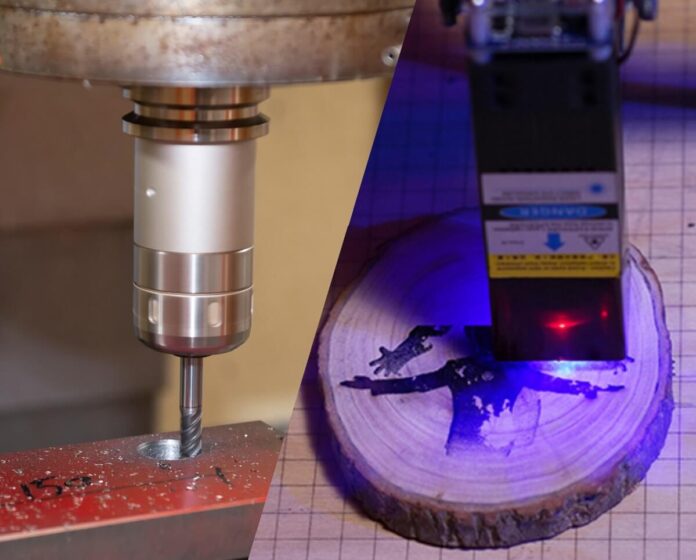

CNC routers and laser engravers are two types of machines that are often used for cutting and engraving materials. While these machines may seem similar at first glance, there are some significant differences between them. In this blog post, we’ll discuss the differences between CNC routers and laser engravers and examine the pros and cons of each one.

CNC Router vs Laser Engraver: what’s the Differences?

A CNC router is a machine that is used for cutting and shaping materials such as wood, plastic, and metal. The tool head of a CNC router is typically a spinning router bit that cuts away material from the workpiece. CNC routers are programmed using computer-aided design (CAD) software and are capable of cutting materials with a high degree of precision. A laser engraver, on the other hand, is a machine that uses a laser beam to etch designs or text onto a material. The laser beam is directed onto the surface of the material, and the material is heated to create a mark. Laser engravers are often used on materials such as wood, leather, and plastic.

Pros and Cons of CNC Routers and Laser Engravers

CNC Router Pros

CNC router offer many advantages to users, making them a popular choice for many industries. One of the main benefits of CNC routers is their precision. They are able to make incredibly accurate cuts and shapes, which is essential for industries such as woodworking, manufacturing, and prototyping. CNC routers are also faster and more efficient than traditional manual methods, allowing for increased productivity and cost savings in the long run. They can also perform complex cuts and shapes, which would be difficult or impossible to achieve by hand. CNC routers can be programmed to repeat the same cut or shape multiple times, ensuring consistency and accuracy across a large number of pieces.

CNC Router Cons

While CNC routers offer many advantages, there are also some potential drawbacks to consider. One of the main issues is the initial cost of the machine, which can be quite high. This may be a barrier for small businesses or individuals who cannot afford the investment. Additionally, CNC routers require a significant amount of training and expertise to operate effectively. This may be a challenge for individuals or businesses that do not have the resources to invest in training or cannot spare the time to learn. CNC routers can also produce a lot of noise and dust, which can be hazardous to operators and may require additional safety measures. Finally, CNC routers may not be suitable for all materials or designs, and may require different cutting tools or settings for different materials or designs.

Laser Engraver Pros

laser engravers offer many benefits to users, making them a popular choice for many industries. One of the main advantages of laser engravers is their precision. They can create incredibly detailed and accurate designs, which is essential for industries such as jewelry making, personalized gifts, and signage. Laser engravers can also work with a wide range of materials, including wood, plastic, metal, and even some fabrics. Additionally, laser engravers are fast and efficient, allowing for increased productivity and cost savings in the long run. They can also create unique and intricate designs that would be difficult or impossible to achieve by hand.

Laser Engraver Cons

While laser engravers offer many advantages, there are also some potential drawbacks to consider. One of the main issues is the initial cost of the machine, which can be quite high. This may be a barrier for small businesses or individuals who cannot afford the investment. Additionally, laser engravers can produce a lot of heat and fumes, which can be hazardous to operators and may require additional safety measures. They may also require regular maintenance and calibration to ensure accurate and safe operation. Finally, laser engravers may not be suitable for all materials or designs, and may require different settings or attachments for different materials or designs.

Conclusion

When it comes to choosing between a CNC router and a laser engraver, it really depends on the job you need to do. If you need to cut thick or complex materials, a CNC router may be your best bet. However, if you need to create detailed designs on small parts, or if you’re working with materials that can’t be cut, a laser engraver may be the way to go. Ultimately, the decision is up to you, and you should choose the machine that best fits your needs.