You must be wondering what WMS actually is or how it functions. Well, this article will help you answer those specific questions. Warehouse Management system, in brief, is a warehouse managing system that is run by software so everything is in line and accounted for. There is advanced technology and sub-systems in place to help with the process of maintaining a warehouse. There obviously a lot of pressure in maintaining a perfect warehouse with well endowed inventory and storage systems in place. WMS helps along with that and smoothens the process.

What is a warehouse management system?

A warehouse management system (WMS) is a piece of software that helps to support and improve warehouse and distribution center operations. A modern WMS will be able to connect to a variety of communication (radio frequency), automatic ID (barcode, RFID, etc.) and automated material handling technologies (conveyor).

The WMS accepts orders from the underlying host system, which is typically an ERP system, stores them in a database, and then sends them to the associated conveyor control systems. Receiving, inspection, and acceptance, put-away, internal replenishment to picking points, shipment (loading into carrier trucks), and other warehouse duties are all supported by warehouse management systems.

Are there any varieties of WMS?

Yes, there are several types or varieties of WMS. There are multiple methods of implementation that exist for WMS, specifically.

Many SME businesses use complex WMS software. There are specific designs or customisations available for specific goods and services. In many cases, ecommerce seller individuals use this type of softwares for their advantage and to meet overwhelming customer demand. Even enterprise companies prefer WMS because of its efficiency.

What is the function of a WMS?

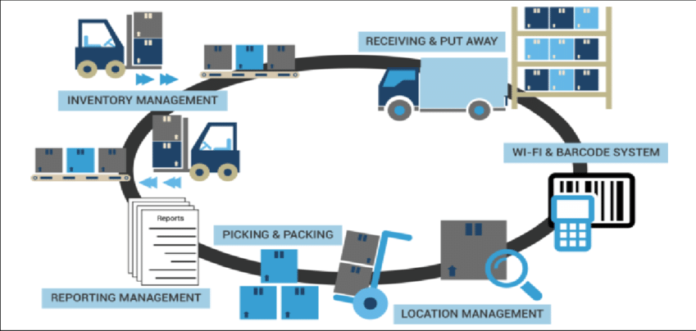

In supply chain management, a warehouse management system (WMS) is critical. The functions that enable these motions, such as inventory tracking, picking, receiving, and putaway, are handled by a WMS. Warehouse Management System helps in keeping the inventory in check by optimizing space in existing storage. As companies discover the benefits of running systems in the cloud, cloud-based warehouse management systems are becoming increasingly widespread. The fundamental difference between a cloud-based WMS and a typical on-premises system is that the WMS vendor or a cloud service provider hosts and manages the software. This relieves the IT staff of the task of implementing, managing, and upgrading the system.

How supply chains function regarding WMS?

To track goods and replenish orders, management and sales teams obtain a precise, real-time picture of various stages of shipment. Orders are sent out faster with better pick accuracy and timeliness, which means more orders may be completed at the same time. This saves money on labor hours, administrative expenditures, and the cost of not getting the following order out quickly enough. The WMS makes it easier to keep track of inventories and locate things for shipping or assembly.

Data from your WMS can be used to assist management in making strategic decisions that will help you expand your organization. This also helps in meeting the demand for storage space during seasonal shifts. You’ll be able to build strong, long-term supplier partnerships based on practical, precise demands and on-time delivery. You’ll have more time to focus on customer satisfaction if your suppliers deliver on time, your warehouse is running well, and your projections are up to date. Reduce product damage, improve delivery times, and eliminate picking errors that cause customer complaints.

Conclusion

Despite the fact that implementing and operating a WMS is difficult and costly, firms reap various benefits that outweigh the complexity and expenditures. A Warehouse management System can help a company save money on labor, enhance inventory accuracy, increase flexibility and responsiveness, reduce picking and shipping errors, and improve customer experience. Modern smart warehouse management systems work with real-time data, allowing the company to keep track of the most up-to-date information on orders, shipments, receipts, and any other products movement.