Every eCommerce business needs Inventory management for the cash flow. In this careful balancing process, you need to confirm you have sufficient stock to run out of product simultaneously. You have to ensure that you don’t have more products in a warehouse. If the scales are imbalanced, it will cost you more. You are unable to complete orders and fail out on potential customers. If you have surplus inventory, you may have unsold stock that must be written off or marketed at a loss. Whatever might be the scenario, you set your eCommerce business at your risk.

What is inventory management?

You should understand that inventory management is important for any business, whether it is small or large. It saves you from waste, saves costs, and saves time. Maintaining on top of supply makes more customer priority, and it offers people to what are all the products they want. If you don’t have inventory management, introduce your business to the best practices. Most companies worldwide have collapsed due to the shortage of the right procedures and systems.

Stock counts

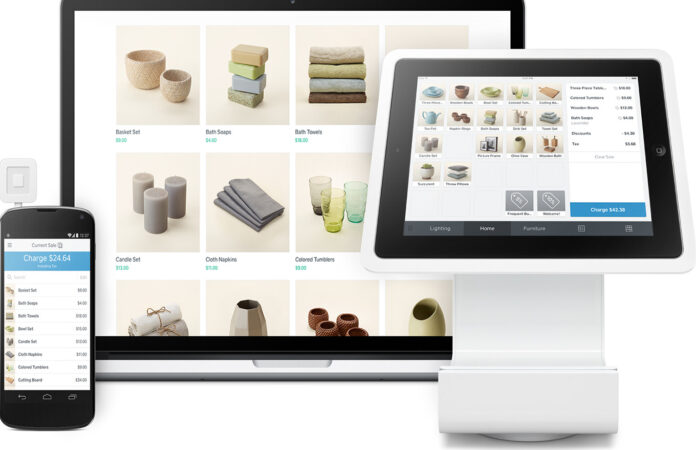

Stock counts are an essential part of success in an eCommerce platform, as this method is known to improve gross profit, lower loss, enhance control of allowances, and reduces waste. Inventory management systems manage the process of all incoming and outgoing products in a retail shop. Inventory management software can perform routine, real-time counts to protect you from potential theft, developing your stock ordering method. It identifies flaws in your pricing strategies and allows your company to meet its goals or achievements.

Automatic reorder points

These retailers may avoid using the reorder point procedure, acquiring products, lowering their inventory costs, and reducing their warehouse spaces. This is another great advantage of providing inventory management systems. And also, this ability to help replace feelings with concrete facts and data will save your team for a great deal of time caused for value-added activities.

Forecast for the Future

You have to include proper inventory management that helps you to analyse inventory forecasting. You can track and manage your inventory storage groups and cash flow, and you will require a better demand plan. If you observe your inventory trends based on a monthly, quarterly, or unit basis, you are able to boost with sales.

Fulfilling orders and managing inventory

Managing inventory through every stage of the product life cycle also comes with a price. Your business incurs inventory costs with every order placed as well. So, you need to calculate the cost of order fulfilment and account for this in your product pricing structure. Some order fulfilment costs to consider include packaging and shipment, labour costs, and the price of any fulfilment platforms or partners you use. You have to calculate the price of the inventory management system you use, ensuring you have selected the most suitable one for your business that needs growth.

Adjust Safety Stock Levels

Inventory management generally feels like you are walking a rope between several stocks on hand and not having enough. You have to produce a plan of inventory, particularly for your products. You have to choose the safety stock and fill it every time you begin to dip into it. If you plan for new stock orders, you have to pay attention and how long it takes your suppliers to produce the things you require.

Final thoughts

If you select the best practices for inventory management, it may be an excellent service in handling your business. It is necessary to create the correct choices to scale and improve your business. You can use inventory management that saves your time, money and enhances customer service.