This post aims to explain all the inquiries you require to ask yourself and your colleagues to make sure that you are acquiring the ideal item of instrumentación y control de nivel. Also, we intend to streamline all the various selections that feature the varied instrumentation that can be utilized in level dimensions.

Having taken into consideration what kind of things that our clients request, we can safely say that the initial demand for any level dimension, level switching, indicator, noticing, detection, or level control is to ask on your own the adhering to 2 questions. I can guarantee your application will drop under one, such as the nature of the level dimension.

(1) Is the concern I require to understand ‘How much?

I.e. what amount is left in storage space, or do I need to understand just how much item there is to ‘manage’ a process?

Or

(2) Is the inquiry I need to recognize ‘when’?

I.e. Do you need to understand when a process stops or begins, require overfill discovery, high level, or completely dry operating?

That is the first major inquiry selected. That is just the start. Let us now go on to define the various other major criteria as well as inquiries that you ought to think about to make sure that you obtain the ideal level measurement tool for your application.

Think about exactly how crucial is the info that you want your brand-new level dimension instrument to measure.

What would certainly take place if you didn’t have this info? What would certainly be the repercussion if you didn’t have these details?

There is a range of value here from the not too vital to a full plant closure and also an environmental disaster, with the wonderful to recognize someplace in the middle of that scale.

A scenario without sufficient level measurement in position could be a plant lacking basic materials and becoming incapable to generate sufficient completed items to meet client needs, which could drastically impact capital. Or possibly having the correct level instrumentation in position might prevent a major contamination incident, as an example leak from an effluent container, saving a company both their reputation as well as a severe fine.

How do you wish to be notified concerning the level measurement details?

You have several options below as information regarding a particular level can be shown in many ways. You can have a visual indicator, an email, text or pager, an alarm system or klaxon, a blinking light, a table on a computer display, a Fieldbus method to a major DCS system, or perhaps an automated closure. What would certainly suit your application best?

Who requires to have access to this level measurement – someone, every person, or just a handful of individuals?

If you want it to, this info can be shown to everybody in the organization. Take a look at the checklist of duties listed below as well as determine that needs to know this level measurement info:

- Plant operators: so that they are protected as well as can examine the measurement as they walk past,

- Drivers: so they understand how much to offload,

- Employees within the main plant control system

- Production coordinators: so that they can prepare when future orders will be satisfied

- Circulation and logistics: to ensure that shipments are co-ordinated,

- Accounts: for supply evaluation purposes,

- Acquiring: so they can be suggested when re-ordering is needed,

- Monitoring: may require level dimension details for strategic decision making,

- Sales team: Will certainly need to know supply degrees for when customers put orders

- Material suppliers/vendors: to arrange shipments of raw materials.

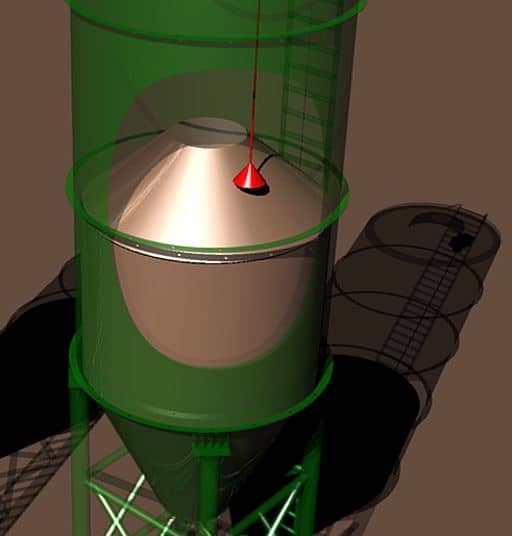

Following you need to take into consideration the procedure and also its conditions. Things like material compatibility, stress, Sensor de nivel, and process, and also item compatibility. Do you need any kind of unique standards on your level instrumentation like safety or hygiene accreditation?

A few other questions you need to ask on your own related to this area are:

- What is the dimension of the vessel, container, or receptacle variety that you require measuring over?

- Just how exactly do you require the measurement to be – nearest millimeter of the meter?

- Do you need a pattern or absolutely precise measurement?

- The next point you require to think about is ‘connectivity.

- Consider what and also where the connections are when it comes to both the procedure and devices. Some more questions you can think about are below:

- Is the plant easily accessible?

- What alternatives are available for electrical wiring, power, accessibility as well as installation of instrumentation?

- Are their choices or actual needs for non-contact or get in touch with measurement?

- Are any type of regional indicators or protocols are needed to attach plants and PC networks?

- Finally just how will the solution to these inquiries impact the decisions already made?

- What about setup, compatibility, and also support?

It is needed to consider whether you need to liaise with electric departments or specialists to obtain the level instrumentation mounted. You could require mechanical staff on standby if vessel alterations are called for, and even the IT division if the level dimension information is to be communicated by a computer system and networked.