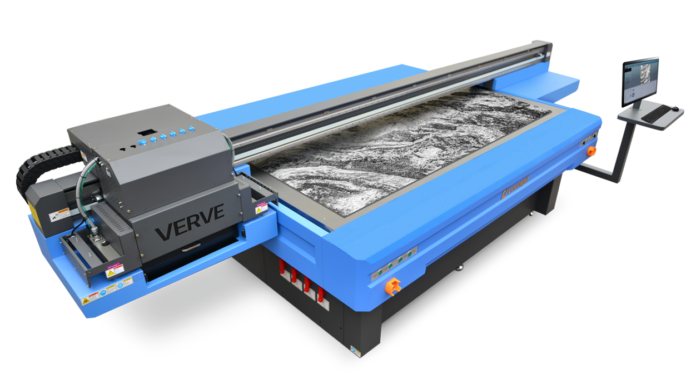

Digital printing on wood is a relatively new process. Because digital designs can easily be printed directly onto wooden substrates. there may be an immediate decrease in traditional method. And the associated high costs associated with the process. Additionally, since digital printing can print straight parallel on a thin sheet, there will be a substantial increase in the production of flatbed printers.

The advantages of digital printing vs. photo printing have been debated for quite some time. Photo printing involves using chemicals to imprint a photograph. These chemicals react with the original image and create a permanent copy. The most popular method today is inkjet printing.

The most common method of digital printing on wood is called direct printing. This is done with the help of wood printing machine, where the ink is applied directly onto the wood. There are three different ways to apply the ink including rollers, sprayers and even needles. Each method has its pros and cons. It’s best to combine several of these methods for the best result.

For digital printing on wood, it’s best to get a high resolution image. The higher the resolution, the better the quality of the finished project will be. Since it’s a two way process, a lower resolution means the image won’t be captured onto the wood directly. This means that the design needs to be transferred from the computer onto the wooden surface using some type of media.

There are different advantages and disadvantages to each method of direct printing. Direct printing allows the artist to manipulate the image directly onto the wooden surface. Although it can create a fine, intricate design, it’s not possible to stretch the image in any way using this method. Also, if a mistake is made, a wood print can easily be corrected using a cloth and paint.

The inkjet printers used in wood printing are much faster than any other type of printer. Because of the nature of the ink, they tend to produce prints with a vivid, life-like color. The ink used in inkjet printers is water-based, which is less likely to smear than other types of inks. These printers are often used by furniture makers because of their ease of use.

Rolled substrate materials are generally not recommended for digital printing on wood because it can actually damage the wood over time. The rollers inside the machine should be regularly cleaned to prevent warping and the ink not sticking to the surface as easily. It is important to avoid placing sharp objects on the rollers which could chip the wood grain. Also, care must be taken when moving the printer around so that the rollers do not become damaged. When on the rollers, use only the roller wheels on either side to avoid damaging the wood grain permanently.

Another alternative when considering the possibility of digital printing on wood is to use a wood laminated mdf board instead. This wood substrate is not as durable as a standard wood substrate and the quality of print tends to suffer slightly. However, it does have the advantage of being easier to clean. It also has more color options available to the designer. Wood laminated mdf board is typically coated with a polyurethane coating that will protect it from ultraviolet light damage.

There are many reasons why digital printing on wood laminated mdf board is not recommended. One of the biggest problems is that UV printers tend to produce orange tones that will make the wood grain in the photo not as noticeable. Another problem is that UV printers can get clogged with dirt and dust which make the image look pixilated. Finally, UV printers can actually damage the board. For these reasons, digital printing on wood laminated mdf board is not recommended.

Two types of technology that have become popular with designers and printers alike are direct jet inkjet printers and dye sublimation printers. Direct jet printers work by using a jet of compressed air to blast dye sublimation print heads directly onto wood. They offer incredible consistency and excellent quality. While they cost more initially, the cost savings over the life of the printer can far outweigh the initial costs. With the growing popularity of digital printing, there are many new printer technologies coming out each year to replace older technologies. These newer printers offer even more capabilities and cost less than their predecessors.

Some of the newer technologies in photo quality digital print technology include solid ink cartridges, dye sublimation printers, and aluminum oxide printers. All three offer exceptional quality and incredible consistency. In addition to cost, you also have to consider how difficult it can be to install the new technologies. If your project will require a bit of DIY work, you may want to opt for the direct printing option because you can simply print directly onto the wood. Even if you have to pay extra for professional installation, the extra cost is well worth it.