If you’re looking to cut metal, a CNC machine is the best option. They are reliable and offer great results. But before deciding whether you should invest in one, it’s important to understand how they work and how they could help your company succeed. Find out more in this article.

What is a CNC Metal Cutting Machine?

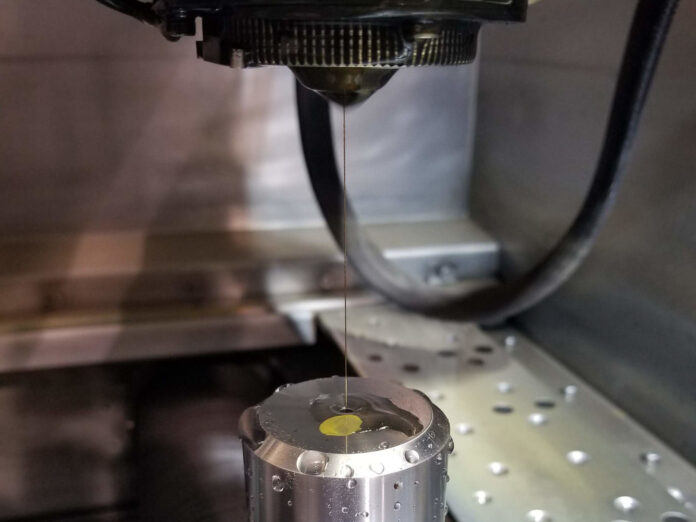

A CNC metal cutting machine is a sophisticated machine used for cutting metal parts with great accuracy. This type of machine is often used in the manufacturing and production of various industrial and commercial products. When considering purchasing a CNC metal cutting machine, it is important to understand the different types of machines available and their respective benefits.

There are three main types of CNC metal cutting machines: wire EDM, arc discharge, and laser. Each has its own set of advantages and disadvantages that should be taken into account before making a purchase.

Wire EDM machines are the most common type of CNC metal cutting machines. They use a wire Feeder System to move the wire cutter head over the part being cut. This system is fast, efficient, and accurate, but it can be slow when working with large parts or those with complex shapes.

Arc discharge machines are similar to wire EDM machines in that they use a wire Feeder System to move the head over the part being cut. However, arc discharge machines use an electric arc instead of a wire to sever the material. This system is faster than wire EDM machines but less accurate. Arc discharge machines also have more difficulty working with large parts or those with complex shapes.

Laser machining systems are the most accurate type of CNC metal cutting machine available, but they also tend to be the most expensive. They use a laser beam to cut through materials instead of an electric arc, which results in greater

Benefits of Using a CNC Metal Cutting Machine

A CNC metal cutting machine is a valuable tool for businesses that need to produce high-quality parts quickly and efficiently. Here are some of the benefits of using a CNC metal-cutting machine:

1. Precision – A CNC metal cutting machine is capable of producing extremely precise cuts, which means your parts will be accurate and fit perfectly together.

2. Speed – A CNC metal cutting machine can cut through metal quickly and easily, making it a fast and efficient way to produce parts.

3. Accuracy – A properly calibrated CNC metal cutting machine will deliver accurate results time after time, making it perfect for precision manufacturing tasks.

4. Durability – A CNC metal cutting machine is built to last and handle harsh conditions, making it a reliable choice for businesses that require high-quality parts rapidly.

How to Choose a CNC Metal Cutting Machine?

Choosing the right CNC metal-cutting machine can be a daunting task, but there are a few key things to consider. Here’s what you need to know to make an informed decision:

1. What Are Your Needs?

Before you can choose the perfect CNC metal cutting machine for your business, you first have to figure out what your specific needs are. Do you need precision cuts? Bigger cuts? More speed? All of the above? Once you have a good idea of what you need, you can start narrowing down your options based on that information.

2. Cost and Budgeting

One of the biggest factors when choosing a CNC metal-cutting machine is cost. You don’t want to overspend on something that won’t be worth it in the long run, so make sure to factor in your budget when assessing your options. There are plenty of affordable machines out there, so don’t be afraid to search for one that fits within your budget without sacrificing too much quality.

3. Size and Weight

Another important factor to consider is size and weight. You probably won’t want a huge machine that takes up a lot of space, and you don’t want something too heavy to carry around or operate easily. Go ahead and take measurements of where you plan on placing the machine and figure out how much weight it can support before making a purchase.

How to Use a CNC Metal Cutting Machine?

A CNC metal cutting machine is a precision machine that can cut metal sheets with amazing accuracy. They are commonly used in the manufacturing of parts for aircraft, cars, and other vehicles. If you’re thinking about getting a CNC metal-cutting machine for your business, here are four things you need to know.

1. What Is the Machine Good For?

The main use of a CNC metal cutting machine is to make precise cuts in metal sheets. This is useful for many things, such as making parts for aircraft, cars, and other vehicles.

2. How Much Does It Cost?

There is no definitive answer to this question since the price varies depending on the specific model and features of a CNC metal cutting machine. However, in general, expect to pay around $10,000 – $50,000 for a high-quality machine.

3. What Are the Limitations?

One limitation of CNC metal cutting machines is that they cannot handle very thick or heavy sheets of metal. They also require more space than traditional manual saws or mills to operate correctly.

4. Who Should Use a CNC Metal Cutting Machine?

If you’re looking for an extremely accurate way to cut metal sheets, then a CNC metal cutting machine is perfect for you! However, if your goal is just to create some simple parts quickly and cheaply, a traditional manual saw or the mill may be more suited.

Conclusion

A CNC metal cutting machine can be a powerful tool in your business arsenal, and if used correctly, it can help you cut costs, increase efficiency, and boost your production. So if you’re considering investing in a CNC metal cutting machine for your business, take the time to learn about the different types of machines available on the market and decide which one is best suited for your needs. Then set up a consultation with a dealer or technician who can help you get started using this valuable tool.